The screeching sun feels like it’s about to come and hug our earth! The only savior for our skin at such times is the sunscreen. The sun’s rays during the day have become so harmful for us that we tend to get a sunburn if we stay long hour out without any protection. Form children to adults and oldies, sunscreen is the best friend for all in the hot summer days. However, have you ever thought How Sunscreens Are Made? What raw material does it require? How it is processed?

Well, a wild thought must have crawled your mind some time or the other. Hence, you have popped up on this page and yeah, we are going to answer all those questions in your mind. So gather this knowledge and tell your kids as well, the ultimate guide to the sunscreen processing. With this, here is How Leather Jackets Are Made!

How Sunscreens Are Made

Before we jump into the topic, did you know why we use sunscreens? Well, it is researched by scientists that the sun’s harmful rays can cause us cancer. These are not the first rays of the sun but the ones that go on throughout the day. A required amount of sunlight is necessary for our skin as it helps to produce melanin, however, too much exposure to the ultraviolet rays or also called as the UV rays may get us some serious skin issues and diseases!

We all know that the sunlight consists of 3 rays, namely, infrared, visible, and ultraviolet. While the infrared and visible rays are no danger, the ultraviolet rays are harmful especially during summers and the peak hours of the sun that are 12-3pm

The ultraviolet Rays are further classified into 3 more types, that are UVA, UVB, and UVC. The UVC radiations are not harmful to the human skin however, the UVA and UVB are. The UVA rays do not burn the skin but penetrate beneath its surface to damage the cell membranes and tissues. The continuous exposure to UVA rays have resulted in hazardous diseases like cancer and is a prime factor for aging. The burning sensation or the sunburns that you ever get are from the UVB rays. They burn the skin and can cause red burn marks. Moreover, they can also tan the skin to an unrepeatable state. The UVB rays also harm the lens and cornea of the eyes. Hence, we wear sunglasses to protect our eyes from it. With this, know How Zippers are Made | Raw Materials, Manufacturing and Quality Control!

Raw Materials

A bunch of chemicals is used in making the sunscreens. Many combinations of natural and synthetic materials are also tried and tested. benzophenone and oxybenzone, avobenzone, PABA (paraaminobenzoic acid), octyl methoxycinnamate and menthyl anthranilate, Titanium dioxide, vitamins E and C, rice bran oil and sesame seed oil, skin-soothing and moisturizing additives such as aloe and chamomile are the things that go into the making of sunscreens.

Also read: How to be a Pro Rider with Driving Lessons in Manchester

The Manufacturing Process

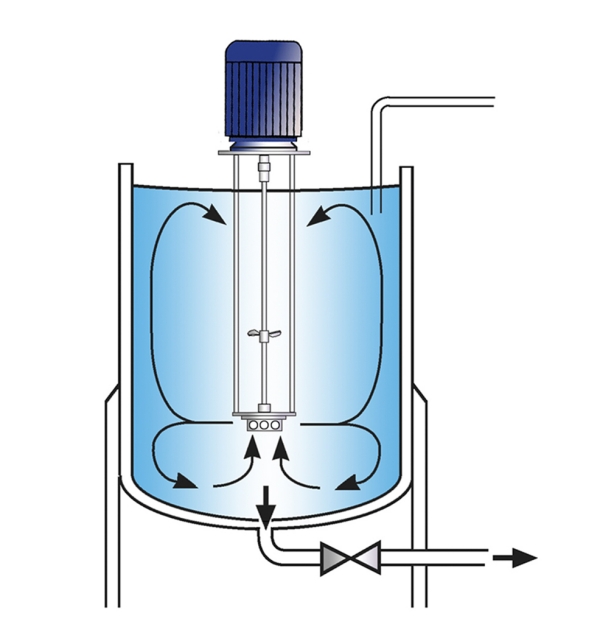

Formulating the lotion- A process called reverse osmosis is used to purify water. It extracts fresh and pure water by forcing it down semipermeable membrane that separates pure water molecules from salts and other impurities.

Each company uses a secret formulation that is only kept to them. The products that are required in the formulation are brought from other industries.

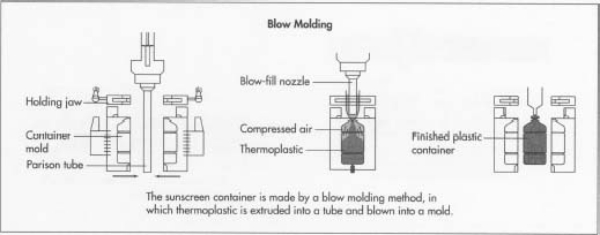

Making the containers- the plastic containers of the sunscreens are manufactured at a place called the blow molding facility. It uses a method in which plastic that molds when heated and hardens when cooled is used. This plastic is called thermoplastics. The containers are made according to the size and shape decided by the company. Any bottle with flaws is rejected however, there is a mechanism to reuse it, and thus the waste is controlled.

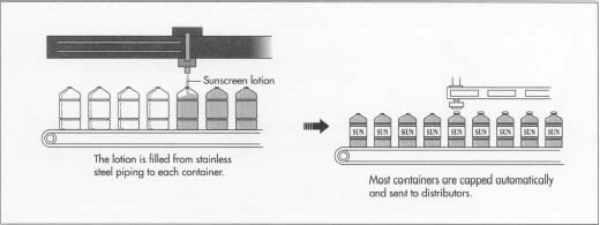

Filling the containers- huge steel takes having capacity 1,000 gallons (3784 1) and more are used in the filling process. This process takes place in a special sterile room with a conveyor system and usually no human so that no infection of any kind affects the sunscreen. The sunscreen flows down special stainless steel vats and fills the containers.

Capping the containers- the containers are capped on the production line itself. This process is automatically done by the machines. Some containers have pump caps that throw out liquid when pressed.

Shipping- after the bottles are filled and capped and the printing process is also done, the bottles are packed into boxes each having 12 pieces grouped together for easy sorting and managing. The boxes are then loaded in the transporter, which takes them to the distributor.

In addition, here are Best and Trendy Hair Color Ideas for Summer!

By-products/Waste

The sunscreen manufacturing companies have taken the great initiative to reduce the waste that they produce of the plastic bottle packaging. The bottles that have defects are molded again. Moreover, sanitized scarp plastic bottles are remolded and used again in making the bottles. The flawed bottles that have already gone through the printing process are supplied to other companies that make patio furniture out of it.

Moreover, here are Trendy Summer Outfits Ideas for Teen Girls to Try!

This was all about How Sunscreens Are Made! We hope you loved reading about it and could grab the maximum knowledge out of it. Remember the type of SPF that you are choosing should be of the one that you really need. The SPF is not harmful to the skin if it is taken in a proper amount. While you are in the house, allow your skin to breathe and only use moisturizers. Moreover, to improve your vitamin D absorption, stand in the first rays of the sun for 10 to 15 minutes daily.

Reply